1. Introduction

As the demand for alfalfa pellets continues to grow in agriculture and renewable energy industries, choosing the right alfalfa pellet making machine becomes a strategic decision. Among the most debated topics in the pelletizing world is whether to invest in a flat die or ring die pellet machine.

This article aims to provide a comprehensive, side-by-side comparison of both technologies and help readers determine which is better suited for their specific production goals, scale, and budget.

2. What is an Alfalfa Pellet Machine?

An alfalfa pellet machine compresses dried and ground alfalfa into dense cylindrical pellets using mechanical force. These pellets are used for:

- Livestock feed

- Biomass fuel

- Soil amendment

Two major types of machines dominate the industry:

- Flat die pellet machines

- Ring die pellet machines

3. Overview of Flat Die and Ring Die Pellet Machines

| Type | Flat Die | Ring Die |

|---|---|---|

| Structure | Die is flat and horizontal | Die is circular and vertical |

| Roller | Rotates on stationary flat die | Stationary roller, rotating die |

| Output | Low to medium | Medium to high |

| Maintenance | Simple | Complex |

| Investment | Lower upfront cost | Higher initial cost |

Each has distinct mechanical designs and operational features that make them suitable for different production setups.

4. Structural Differences Between Flat Die and Ring Die Machines

- Flat Die Machines: Feature a horizontal die plate with multiple holes. Rollers press material vertically into the die holes.

- Ring Die Machines: Feature a cylindrical die with rollers pressing material from the inside out through die holes.

These structural differences lead to variations in pellet output, density, energy use, and durability.

5. Working Principles

5.1 Flat Die Pellet Machine

- Raw alfalfa is fed into the top hopper

- Rollers press material downward through the die holes

- Pellets emerge from the bottom

- Gravity and friction aid the process

Pros:

- Simple structure

- Easy to clean and maintain

- Best for small-scale or home production

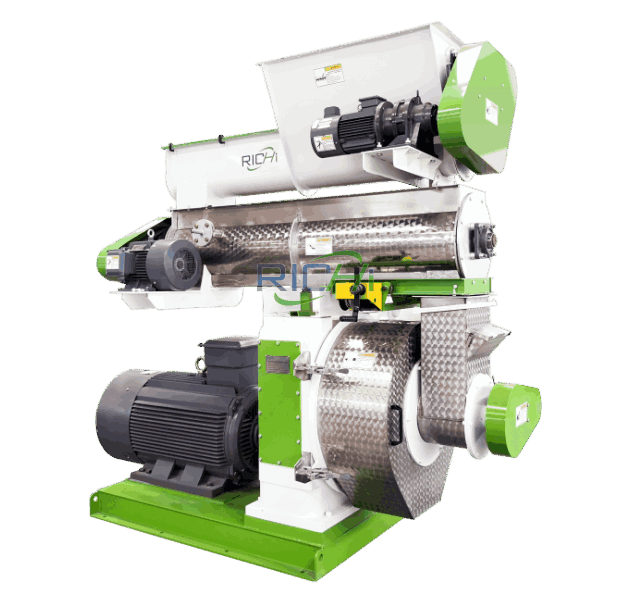

5.2 Ring Die Pellet Machine

- Alfalfa is fed into the center of the ring

- Rollers push material outward through the rotating die

- Pellets exit via a chute

Pros:

- More efficient for large-scale operations

- Better distribution of pressure

- Handles continuous, high-volume production (Related post: Grass Pellet Machine)

6. Output Capacity Comparison

| Machine Type | Typical Capacity Range |

|---|---|

| Flat Die | 50 kg/h to 1 ton/h |

| Ring Die | 500 kg/h to 20+ tons/h |

Ring die machines are clearly superior in output. If your operation demands consistent large volumes, ring die is the better choice.

7. Energy Consumption and Efficiency

Ring die pellet machines tend to:

- Use larger motors (30–160 kW)

- Require more energy per hour, but

- Have better energy-per-ton efficiency

Flat die machines are more suitable when electricity is limited or when fuel consumption needs to be minimal.

8. Pellet Quality and Consistency

- Ring die machines produce denser and smoother pellets, ideal for commercial packaging.

- Flat die machines may produce slightly more varied pellet lengths and density, but are still suitable for farm use.

Quality is influenced by:

- Die compression ratio

- Roller pressure

- Moisture content

9. Maintenance and Durability

- Flat die machines: Easy to disassemble, clean, and repair. Perfect for DIY maintenance.

- Ring die machines: Require skilled maintenance, especially with die alignment and lubrication systems.

Ring dies and rollers also last longer due to better stress distribution.

10. Cost Analysis: Initial Investment vs. Long-Term Value

| Cost Factor | Flat Die | Ring Die |

|---|---|---|

| Initial Investment | Low ($800–$8,000) | High ($10,000–$150,000) |

| Spare Parts | Inexpensive | Expensive |

| Operating Cost/ton | Higher | Lower |

| ROI (Large Scale) | Slower | Faster |

Choose based on your cash flow, volume targets, and expansion plans.

11. Ideal Use Cases for Flat Die Pellet Machines

- Family farms producing 50–500 kg/h

- Small research farms testing feed formulas

- Mobile units for field-based pelletizing

- Budget-conscious startups

- Areas with limited infrastructure

12. Ideal Use Cases for Ring Die Pellet Machines

- Commercial-scale feed mills

- Alfalfa processing cooperatives

- Integrated operations with continuous feedstock

- Export-oriented pellet producers

- Government or NGO-funded energy projects

13. Environmental and Operational Considerations

Ring die machines:

- Emit less dust due to closed feeding

- Operate quieter and more steadily

- Use automated lubrication, reducing waste

Flat die machines:

- May produce more noise and heat

- Easier to run on solar or off-grid setups

- Ideal for rural settings without industrial support

14. Choosing the Right Machine for Different Business Scales

| Business Size | Recommended Machine |

|---|---|

| Backyard farming | Small flat die |

| Village collective | Mid-sized flat die |

| Local feed supplier | Small ring die |

| Regional distributor | Large ring die |

| National feed brand | Industrial ring die |

15. Mobile vs. Stationary Pellet Solutions

Flat die machines are more adaptable to:

- Truck-mounted pellet units

- Barn-based operations

- Situations needing frequent relocation

Ring die machines are better for centralized, high-volume plants. (Related case: 10-12T/H Ruminant Alfalfa Grass Pellet Production Line in Australia)

16. User Experience: Case Studies

Case 1: Ontario, Canada – Small Dairy Farm

Installed a 200 kg/h flat die machine for on-site pelletizing. Reduced feed costs by 35% and saw payback in 8 months.

Case 2: Spain – Commercial Pellet Factory

Operates a 12 t/h ring die line producing alfalfa pellets for export. Uses automatic bagging and cooling, with minimal downtime.

17. Expert Recommendations

- Start small with a flat die model to test local demand

- Scale up to ring die when customer base and feedstock logistics are stable

- Choose reputable manufacturers with after-sales support

- Factor in spare part availability, especially for ring die systems

18. Future Trends in Alfalfa Pelletizing Technology

- Hybrid die machines combining flat and ring technologies

- Smart sensors for real-time monitoring

- AI-powered optimization of pellet density and output

- Eco-design certifications for sustainable machines

Innovation is making both machine types more energy-efficient, smarter, and easier to operate.

19. Conclusion

The choice between a flat die and ring die alfalfa pellet machine comes down to your production scale, budget, maintenance capabilities, and strategic goals.

| Best For | Choose This |

|---|---|

| Small-scale farming | Flat Die |

| Large-scale operation | Ring Die |

| Flexibility needed | Flat Die |

| Uniform quality needed | Ring Die |

Whichever you choose, investing in quality equipment from reliable suppliers and maintaining proper training and upkeep are keys to long-term success in the alfalfa pellet business.

20. Frequently Asked Questions (FAQs)

Q1: Can flat die machines handle other materials besides alfalfa?

A: Yes, they can process grass, rice husk, sawdust, and more with proper die adjustment.

Q2: Is a ring die machine harder to operate?

A: It requires more training, but many come with automatic features to ease operation.

Q3: What’s the lifespan of dies and rollers?

A: Flat die: 500–800 hours; Ring die: 1,000–2,000 hours, depending on use and maintenance.