In the ever-evolving landscape of renewable energy solutions, biomass has emerged as a game-changer, offering a sustainable and versatile alternative to traditional fossil fuels. At the heart of this burgeoning industry lies the pellet mill line, a sophisticated system designed to transform raw biomass materials into compact, energy-dense pellets, fueling the transition towards a greener and more sustainable future.

The Rise of Biomass Energy Biomass energy, derived from organic matter such as wood, agricultural residues, and dedicated energy crops, has gained significant traction in recent years. This renewable energy source offers numerous advantages over traditional fossil fuels, including:

- Reduced Carbon Footprint: Biomass is considered a carbon-neutral fuel source, as the carbon dioxide released during combustion is offset by the carbon absorbed during the growth of the biomass feedstock.

- Versatility: Biomass can be converted into various forms of energy, including heat, electricity, and transportation fuels, making it a versatile and adaptable energy solution.

- Waste Utilization: Biomass energy production can utilize waste materials from various industries, such as forestry, agriculture, and municipal solid waste, contributing to a circular economy and reducing waste disposal challenges.

- Domestic Energy Security: By harnessing locally available biomass resources, countries can reduce their dependence on imported fossil fuels, enhancing energy security and economic stability.

- Rural Development: The production and utilization of biomass energy can create new economic opportunities in rural areas, supporting local communities and promoting sustainable land management practices.

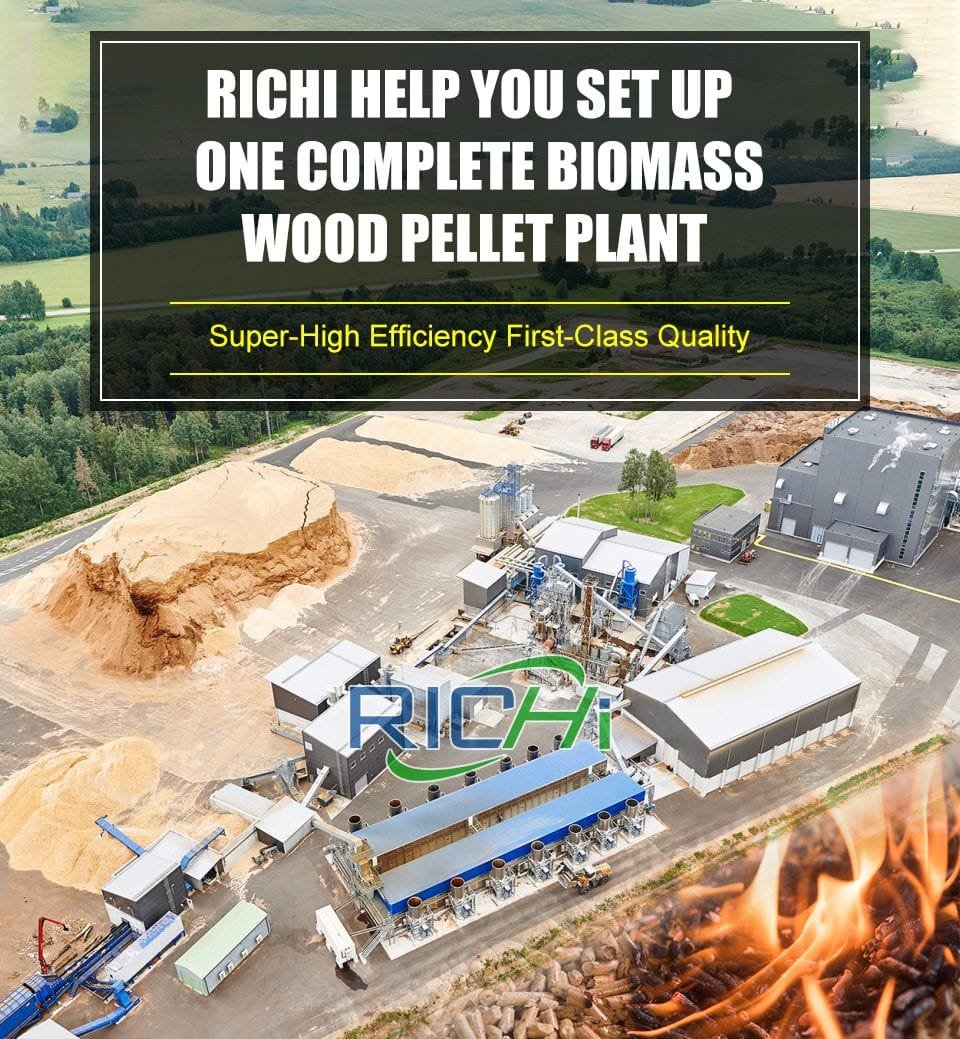

The Pellet Mill Line: A Comprehensive Solution A pellet mill line is a complete and integrated system designed to transform raw biomass materials into high-quality, energy-dense pellets. This sophisticated setup encompasses a range of specialized equipment and processes, ensuring efficient and reliable pellet production. The key components of a typical pellet mill line include:

- Feedstock Handling and Preparation

- Grinding and Sizing

- Conditioning

- Pelleting

- Cooling and Drying

- Screening and Packaging

Factors Influencing Pellet Quality and Efficiency The quality and efficiency of the pellets produced by a pellet mill line are influenced by several critical factors, including:

- Raw Material Quality

- Particle Size Distribution

- Conditioning Parameters

- Die Specifications

- Cooling Rate

- Maintenance and Optimization

Advancements and Future Outlook The pellet mill line industry is continuously evolving, driven by the need for increased efficiency, automation, and sustainability. Advancements in areas such as process control, energy optimization, and alternative biomass sources are shaping the future of pellet production.

One notable development is the integration of advanced technologies, such as the Internet of Things (IoT) and machine learning, into pellet mill lines. These technologies enable real-time monitoring, predictive maintenance, and optimized process control, further enhancing the performance and efficiency of the machinery.

Additionally, the industry is exploring the use of alternative biomass sources, such as agricultural residues, energy crops, and municipal solid waste, as potential feedstocks for pellet production. These alternative sources not only contribute to the sustainability of the industry but also provide opportunities for diversification and resource utilization.

In conclusion, biomass pellet plants are at the forefront of the biomass energy revolution, transforming abundant biomass resources into a versatile and environmentally friendly fuel source. As the world continues its journey towards a greener and more sustainable future, these specialized systems will play a pivotal role in powering homes, industries, and communities with clean, renewable energy, paving the way for a more resilient and sustainable energy landscape.